Burning Rubber

My Dad’s Rolls Royce

Words: Jerry Blanchard+MikeBlanchard Photos: Steve Rosen

When I was young our family car was a 1934 Rolls Royce 20-25 Gurney Nutting two-door saloon. It is to this car that I trace my love of vintage cars.

My father Jerry has always been a devotee of fine engineering, and as a young man he wanted to have the best car he could get. The Rolls had style, fine engineering and at the time was probably not too expensive. So about 1964 he purchased a likely car in England and had it shipped over. I remember going to the docks when it was unloaded. It was like a scene in a noir movie.

In 1965 we moved from Pasadena up to the seaside town of Pacific Grove, out on the point between Monterey and Pebble Beach. PG had been a Methodist summer camp, and by the time we lived there, it had a comfortable sandy-hippy-ish-family vibe not far removed from the era of Steinbeck’s novel “Cannery Row.”

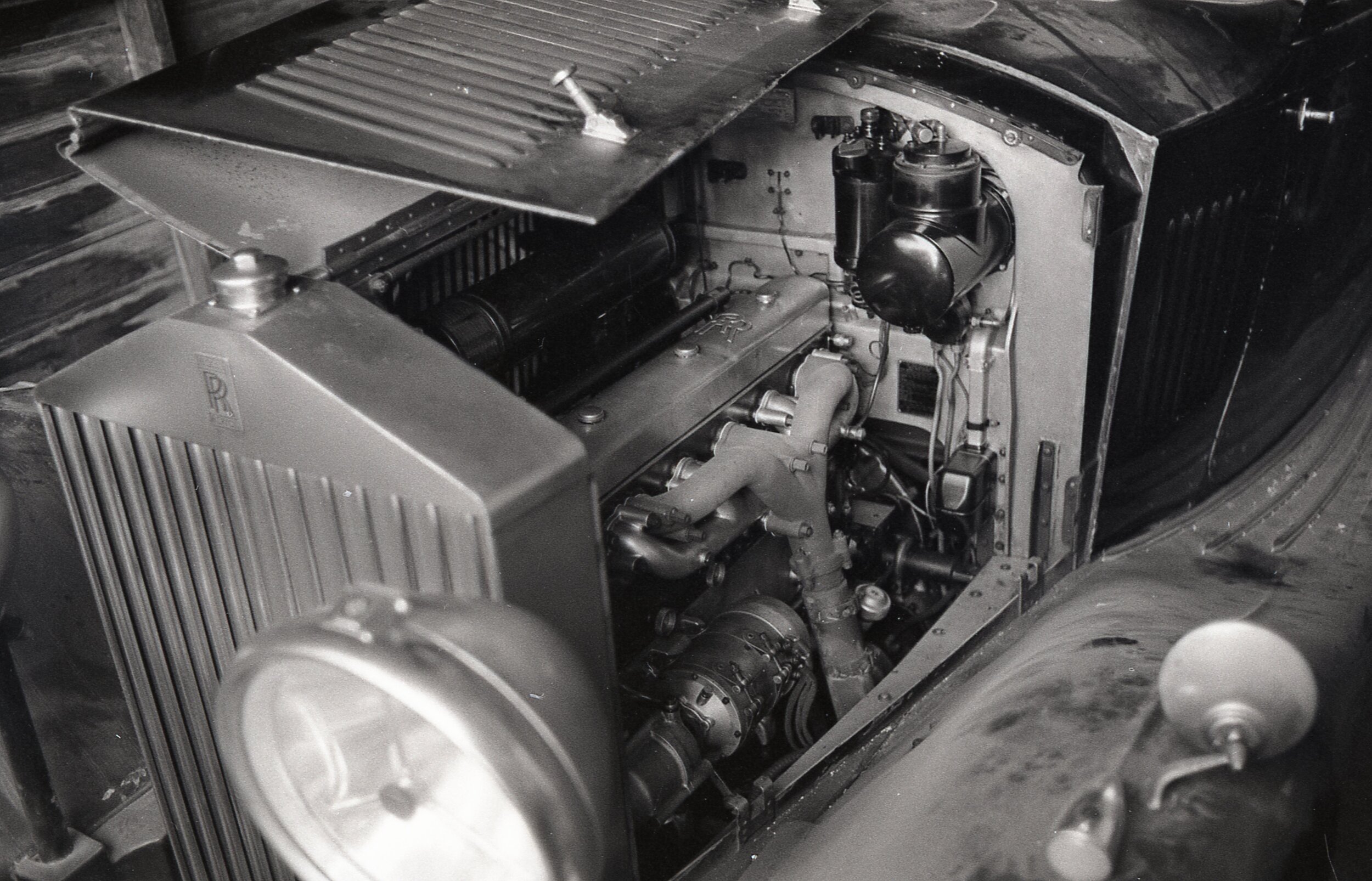

Even as a child I remember a certain sense of pride in our beautiful old car but, as our only car, I’m afraid my siblings and I were pretty rough on its interior. After a bit Dad got a 1949 Chevrolet truck and the Rolls did not get out as much. In the early ’70s he pulled the engine and rebuilt it, which was quite a project.

At the time, Dad taught Metal Shop at Fitch Junior High School out on Fort Ord. He moonlighted at Charlie Cole’s VW/Porsche shop in Monterey, so he had access to good tools and had the skills to work on the car.

The Rolls was a sad victim to divorce in the ’70s, but it went to a local fellow who loves it and who, I believe, still owns it. Recently Dad gave me a sheet of negatives taken in 1970 by his friend Steve Rosen, and they bring back a time and place long gone.

Dad and the Rolls Royce in front of our house with my sister and I standing out front.

Rosen is a fine photographer and an award-winning cinematographer and moviemaker still active in the area.

We believe the photographs document Dad and his friends getting the Rolls running, tuned up and driving after a period of storage.

The photos are a treasured addition to an archive that I have on the car. It contains Dad’s extensive correspondence with the factory, the papers and invoices documenting the rebuild, the owner’s manual, a couple of factory tools and the service radiator cap.

Memory is a weird thing: very plastic and changeable. The photos brought up a lot of questions (and filled in a few fuzzy spots) and they offered Dad the opportunity to reminisce a bit about the car that loomed so large in our young lives.

“I believe I paid $2,500 for it,” he said. “The reason I wanted to get a 20-25 Rolls was because my great mentor and craftsman, Ray Warren Phillips, had one that I admired in my boyhood years when I often worked in his shop. When it came time to get a new car I thought the price of a used Rolls was about the same as a good used Chevrolet, and it might be nice to have a real piece of engineering history. That led to quite an adventure.

“There were some guys in the Los Angeles area who belonged to the Rolls Royce Owners Association, and they gave me copies of the association magazines to read and learn from. I searched the ads in the magazines and found the 20-25 at Mascot Motors in London.

“I phoned the owner of Mascot Motors, and he was most helpful. After I had paid for the car he had his mechanic install a new clutch and fit two new tires because he said the tires on the car were not quite as good as he felt they should be, and he wanted the car to be in good running shape for us. He was a real English gentleman.

“It came over on a Dutch freighter, the Ablaserdyk. It was quite a night getting it. I had to fill the radiator and put in gasoline, and I think I may have taken a battery, too. It started right up on the first roll-over with the crank, but when we were driving home a wire under the back seat shorted on the frame and burned, filling the car with smoke and draining the battery. This happened close to the docks.

“I found the problem, and had to get a battery charge, and we finally made it home. Mascot Motors warned me, the sailors would try to steal the lady (Ed.: the Spirit of Ecstasy hood ornament) so they hid it under the leather upholstery in the back seat in a little pocket they had used successfully in other shipments of cars overseas. When I first saw the car deep in the hold of the ship before they offloaded it, the hood was up, and it was clear the sailors had been searching for the lady.

“I was not allowed to go down into the ship but was allowed to look into the hold before offloading. It was night and very dark and not an easy time.

“The car had a Bijur one-shot oiling system that oils nearly everything on the chassis when a pedal inside the cab is pushed. Small brass tubes deliver oil from a pot on the engine side of the firewall to the leaf springs and fittings all over the chassis, and even to the throw-out bearing in the clutch housing.

“The flywheel has holes drilled around the periphery to let the excess oil drip out. The mechanic in England did not clean out the clogged holes in the flywheel when he fit the new clutch discs, and before long the new clutch started to slip because the oil could not get out. I installed new Rolls factory clutch discs, riveting them on with copper rivets supplied by Rolls Royce in England.

“I rebuilt the engine because it had a lot of miles on it and I wanted to make it as perfect as I could. I could have probably left it alone and just run it, but I did discover some issues that needed attention. The crankshaft is hollow, and over many years of whirling with the early type of non-detergent oils, hard deposits of abrasive dirt and grit had accumulated inside the crankshaft. I had to drive them out with a wood dowel and hammer, and they filled a small coffee can.

“One of the bronze bearings in the gear train on the front of the engine had seized on its shaft, and the gear was spinning on the bearing. Fortunately, I found the problem early enough that nothing was ruined, and a new bronze bearing and polishing the shaft put things right.

“Dave Taylor lived in Carmel Valley, and he owned a beautiful Rolls Royce Silver Ghost single-seat roadster. He was most helpful with advice during the engine rebuild. He had a fine machine shop at his home and was very gracious in letting me work in his shop to do the fitting of the main bearings to the crankcase and to do other work on the engine. He had the correct Whitworth wrenches and loaned me what I did not have. Dave is the inventor of the famous Zebra golf putter.

“Babbitt Bearing Co. in San Jose ground the nitrided crankshaft and line-bored the Babbitt metal main bearings after I fit them to the engine. The rear thrust bearing and the front and middle bearings I got new from Rolls in England. All the bearing shells came as complete circles, which I cut in two with a hacksaw and filed and fit them to a proper “crush” fit in the engine per instructions in the Rolls factory manual.

“All main bearings are steel shells lined with Babbitt metal, which is thick in order that any size crankshaft can be fit to the bearings. The six-cylinder engine has seven main bearings. The four intermediate bearings were no longer available from Rolls Royce in England, so Babbitt Bearing machined new steel rings and lined them with Babbitt by spraying it in with a flame gun.

“I had Babbitt Bearing re-line the original bearing shells with Babbitt, but a careless workman ruined all the bearing shells by sanding the contact faces, which destroyed the “nip” or crush-fit in the aluminum crankcase. They paid for new bearings, but we were both pretty unhappy with their mess-up, and it was a stressful time.

“I sawed and fit those intermediate bearing shells the same as the other three genuine Rolls bearings. I spent the day at Babbitt Bearing for the line boring and the boring and honing of the cylinders. I assembled the cylinders and head on the crankcase and torqued the head down to put the engine in condition for line boring on a very large, horizontal boring machine. The man who did the boring work really knew his stuff.

“Babbitt Bearing did a large amount of aircraft engine work, so they knew their business. They also bored the cylinders on the Rolls engine and had a large reciprocating vertical hone to create the proper cross-hatch pattern in the cylinders.

“The rebuild of the engine, I think, took over a year. It was a big and difficult job.”